Powder Metal Components

Cook-Leitch Inc. has specialized in Powder Metal (P/M) components since our inception in 1964. In 1984, Cook-Leitch Inc. joined Eastern Sintered Alloys, Inc. (ESA) and we provide new account development, program management, engineering and quality support for ESA and our customers throughout the Midwest USA and Mexico.

We are engineering driven! We offer:

- Product development support to our customers.

- Part design and assembly design assisitance.

- Powder Metal material selection based upon our customer’s application.

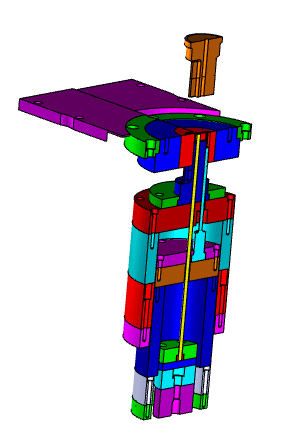

- Our experienced engineering team utilizes Solidworks (2024).

- We have specialized engineering software for designing Gears.

- We design all P/M tooling at our factory.

- We maintain our customer’s tooling for the life of the program.

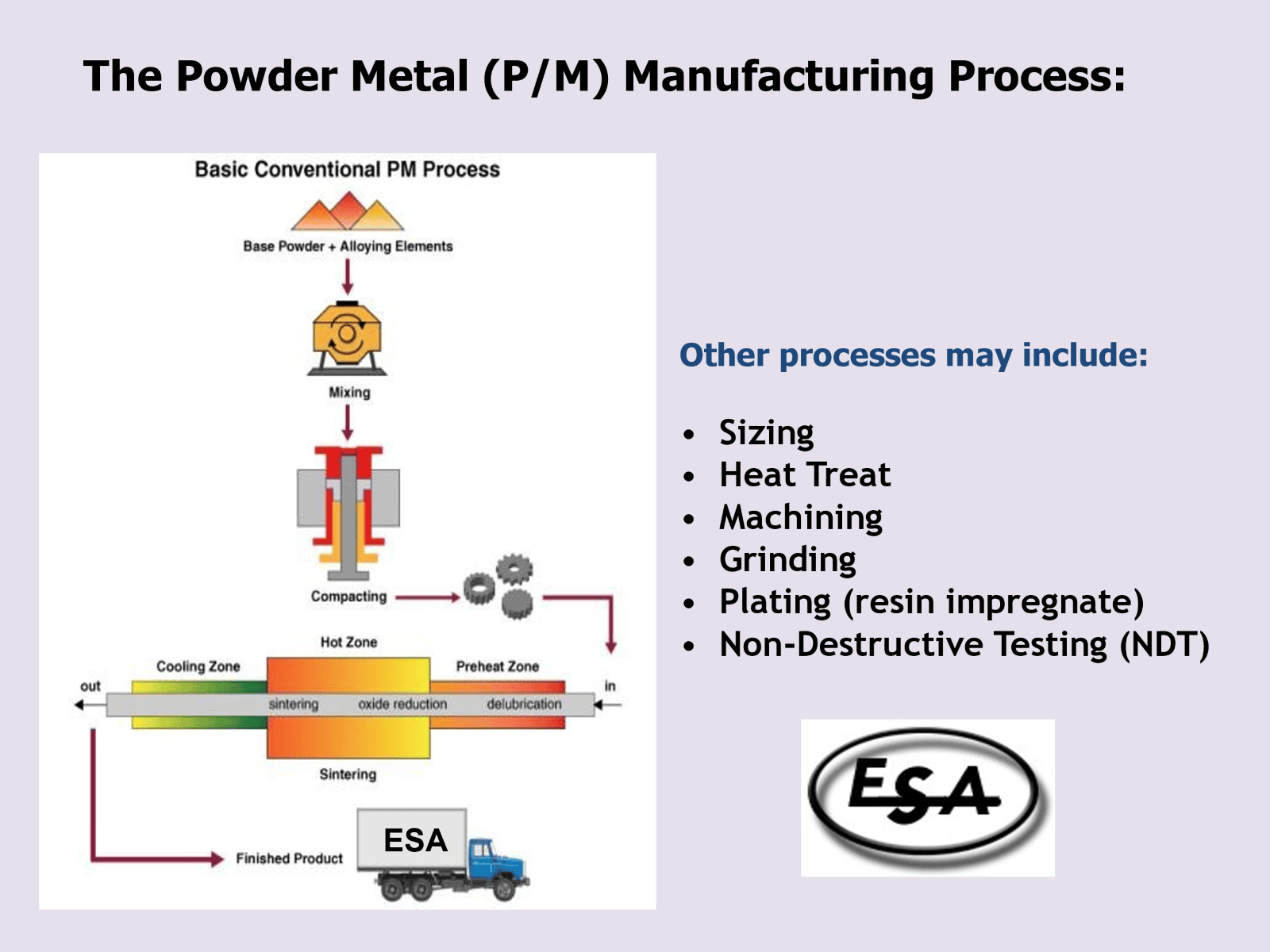

The Powder Metal (P/M) Manufacturing Process:

Cook-Leitch Inc. Speed to Market via our Powder Metal (P/M) parts manufacturing process:

- Our prompt, efficient engineering support will assist in the design of a robust P/M part for each customer’ application.

- Our tool design, tool build, and PPAP submittal process is typically within a 6-10 week timeframe.

- We have a disciplined Advanced Product Quality Planning (APQP) process which involves our customer’s input. This teamwork approach solidifies a safe & successful product launch.

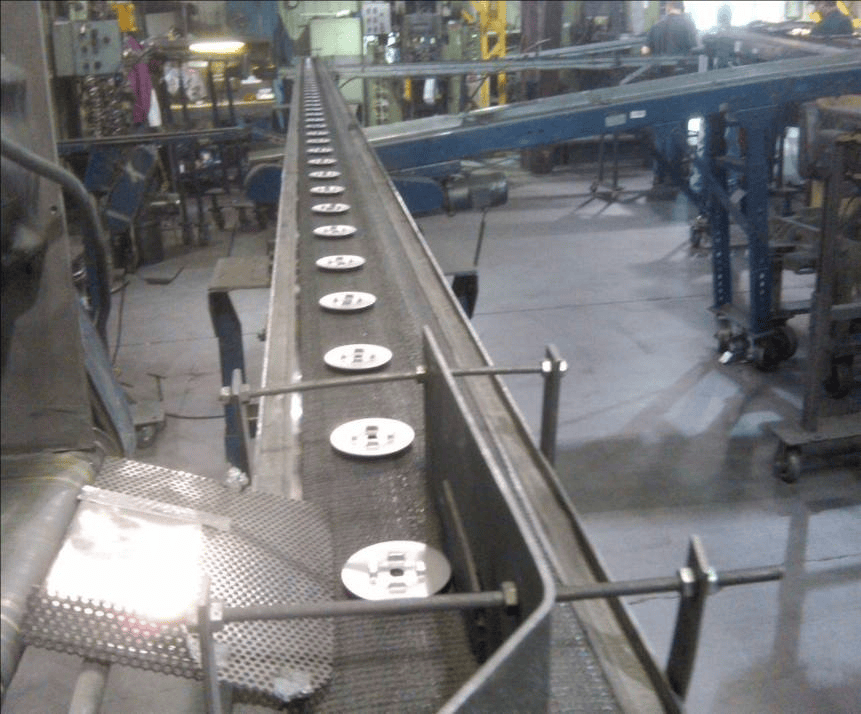

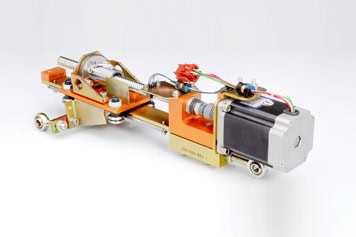

Our Powder Metal manufacturing process: Highly Automated!

- We are a global leader in the production of Powder Metal parts. We ship in excess of 1.1M pieces per day throughout the world.

- Our 92,000 square foot faciliy in St. Marys, PA has a significant competitive edge-

- We have a highly-automated, robotic-oriented facility which results in production efficiencies and the production of high-quality P/M parts.

- Cook-Leitch Inc. specializes in “safety critical” P/M components in the automotive (steering, seating, brake systems, etc.), lawn & garden (transmissions), fluid power/hydraulics, heavy truck & agriculture, among other industries.

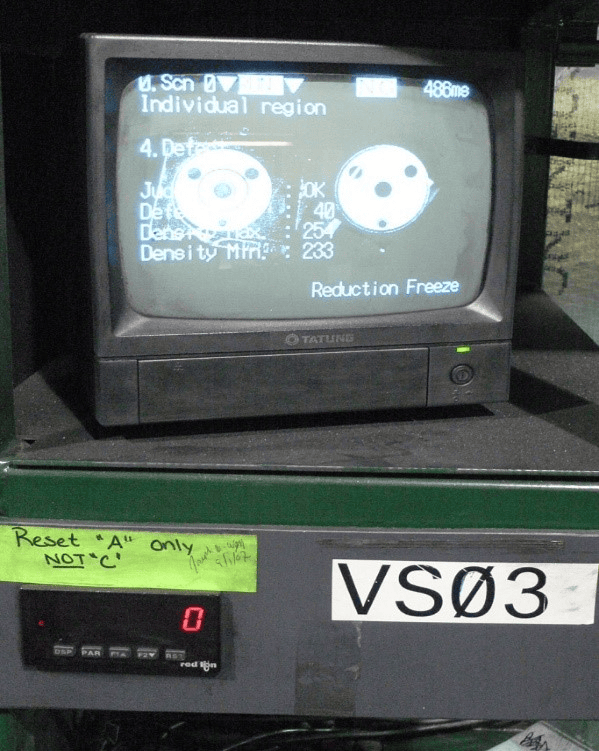

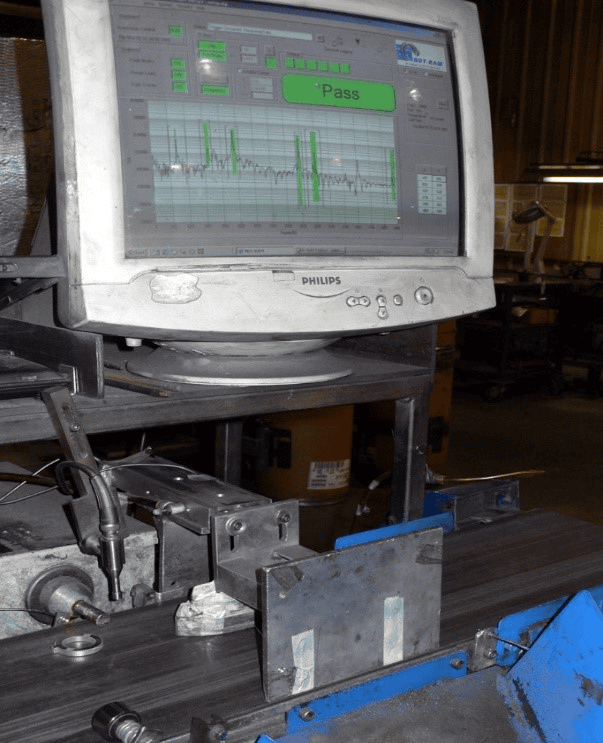

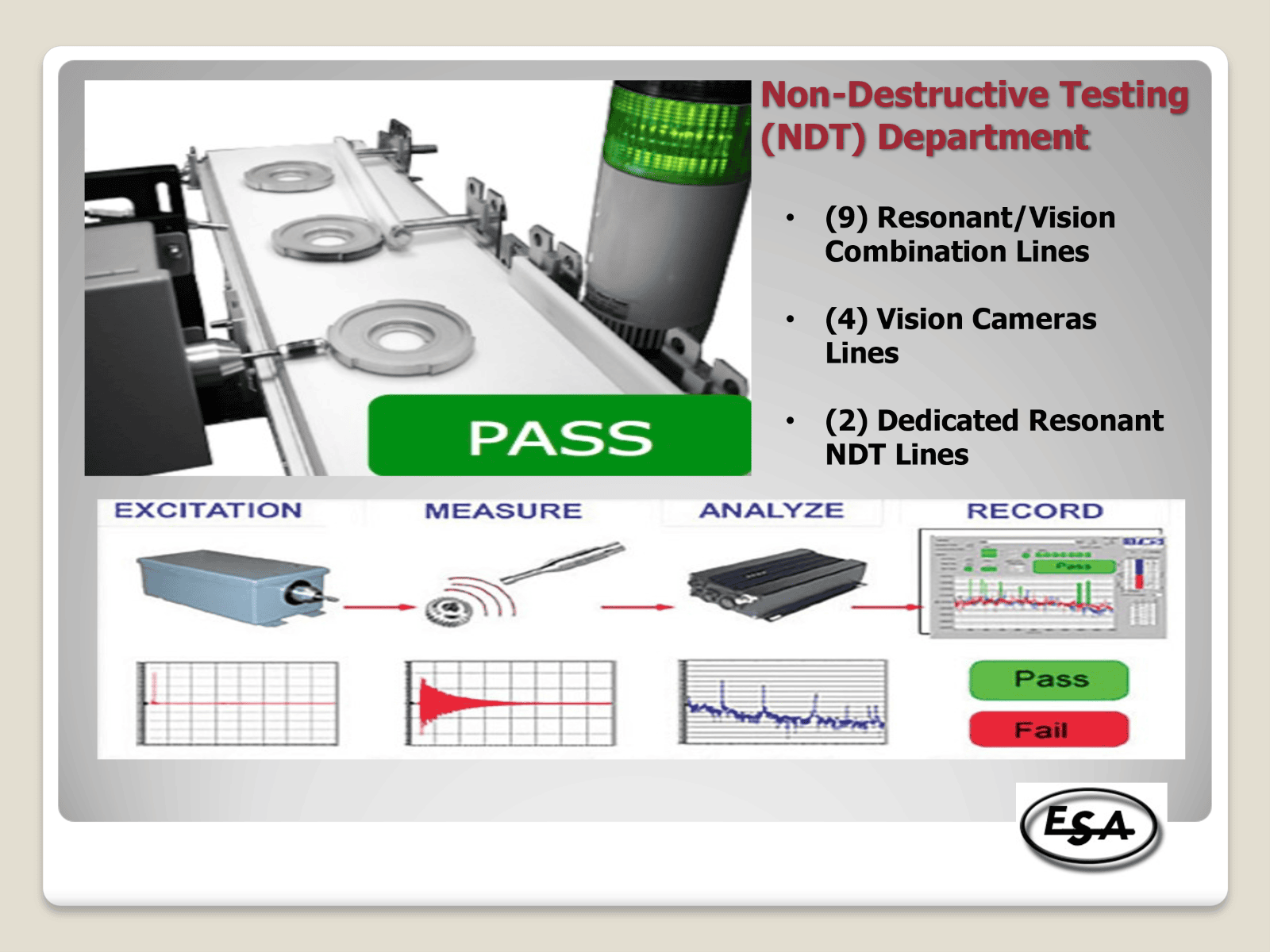

- Our facility has an unparalleled Non-Destructive Testing (NDT) department-both vision and resonance-to complement our high-volume automated production approach.

- We can 100% inspect our customer’s critical P/M parts.

- Our vision & resonant inspection systems are designed and developed by our manufacturing engineering team for each safety critical P/M component.

- Our St. Marys, PA facility has 220 dedicated, well-trained associates. We are committed to customer satisfaction!

For Seven (7) Decades Cook-Leitch Inc. has specialized in the manufacturing of a variety of Powder Metal (P/M) parts:

Bearings (Straight-Wall, Spherical, Flange, etc.) & Bushings-

- We have been a leader in the production of P/M bearings and bushings since the 1960’s.

- We have been entrenched in the motor (starter motors, windshield wiper, door lock, etc.) and transmission industry for many decades.

- We offer bronze, diluted-bronze, iron graphite, and unique bearing material blends for your bearing/bushing application.

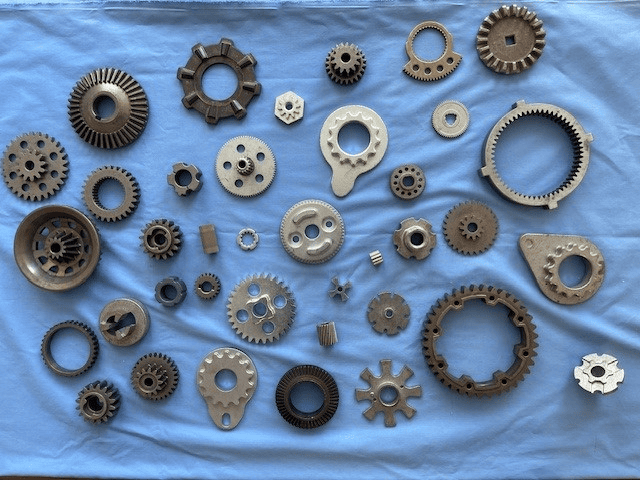

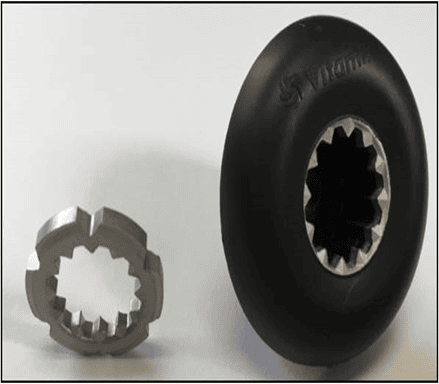

Gears (Cluster, Compound, Helical, Pinion, Planet, Ring Gears, Sector Gears, and Sprockets)-

- We support our customers with Gear part design assistance.

- Our P/M gears are used in a variety of applications including agriculture, automotive seating & steering, appliance, fluid power/hydraulics, hand-power tools, heavy truck & bus, lawn & garden, off-highway equipment, transmission, among other applications.

- Many of our P/M gears are produced from sinter-hardened (air-hardened) materials which provide higher density and higher strength gear technology for our customers.

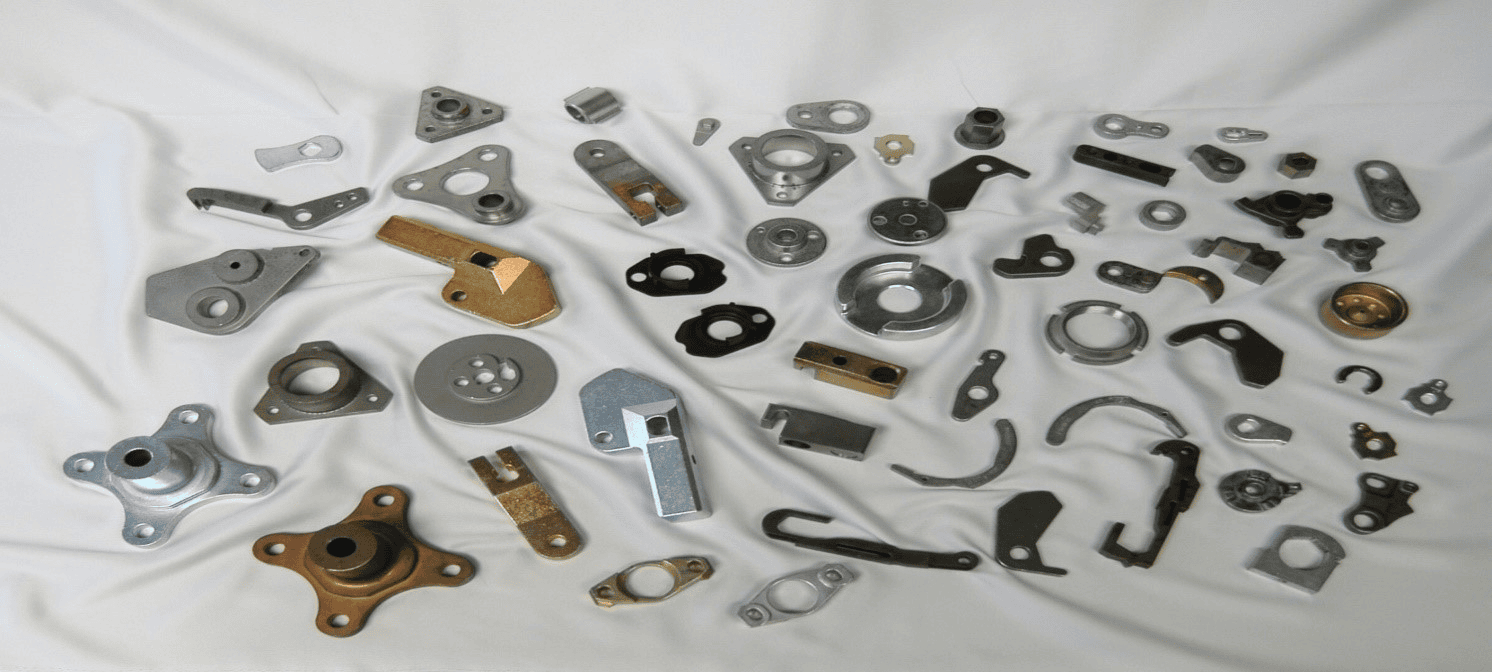

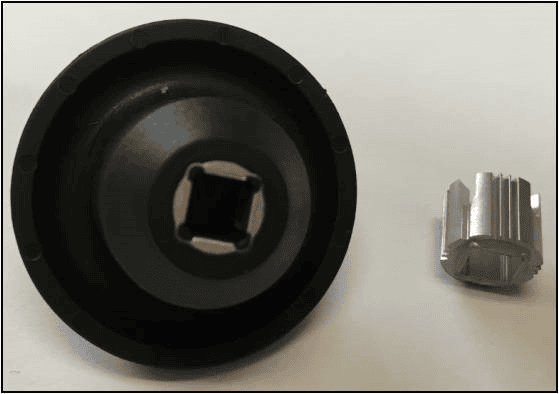

Structural P/M Parts-

- The key benefits of Powder Metal’ technology when producing a “Structural” part:

- Molding a Structural P/M components to a “Net Finalized Shape” (with no machining or minimal machining).

- Tooling is quick to design & build (8-10 weeks).

- The P/M’ process is a “green technology-conversion of scrap material into atomized, highly specified materials.

- We can offer a variety of material options (iron, iron-copper, high-strength alloys with nickel, stainless steel, sinter-hardened materials, etc.) for Structural P/M parts depending upon our customer’s specific application.

- The P/M process offers excellent surface finishes.

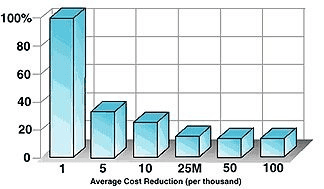

- We can often convert a more expensive manufacturing process (i.e. fine-blank stamping, machined part from bar stock, traditional stamping, die cast part, etc.) to a P/M part for significant cost-savings!!

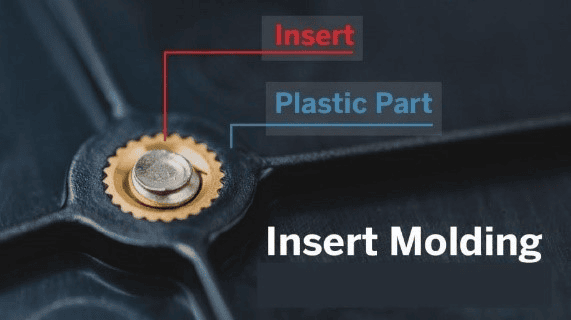

Insert and Over-Molding of Powder Metal (P/M) Parts-

- We offer hybrid Polymer (Plastic Injection Molding) and Powder Metal combination components.

- This hybrid provides part weight savings, and part aesthetic advantage. The P/M insert provides the assembly additional strength while the plastic injection insert/over-molded part brings its’ advantages.

- The P/M part is easy to robotically feed into the molding machine based upon the repeatable, consistent P/M process.

- We work with a variety of OEM customers and plastic injection molding companies to develop a robust plastic molded-powder metal design.

Our Powder Metal (P/M) Capabilities:

- (82) molding presses-4-ton to 300-ton (approximately 10 square inches)

- (24) sintering ovens

- High-temperature sintering (air-harden sintering).

- (16) sizing presses-high-speed sizing of bearings (straight-walls, flange, spherical, etc.), spacers, bushings, etc.

- Copper Infiltrating and other high-strength materials to meet our customer’s specific application.

- Warm compaction technology to achieve higher-density and higher strength P/M parts.

- The Metal Powder Industry Federation (MPIF) is committed to “Green Technology”-see video below, “The Sustainability Continuum.”

Diversity of Custom Powder Metal (P/M) Parts:

- Actuator Levers

- Armatures

- Bearings

- Straight-wall

- Flange

- Spherical

- Bushings

- Cams

- Clamps

- Compression Limiters

- Counterweights

- Gears

- Helical (19 degree)

- Sector Gears

- Compound Gears

- Pinion Gears

- Planet Gears

- Ring Gears

- Sprocket Gears

Powder Metal (MPIF) Materials:

- High Strength Alloys

- High Density Materials

- Air-Hardened Materials

- Stainless Steel

- Bronze (90/10)

- Diluted Bronze

- High Temperature Sintering

- Copper Infiltration

- Iron Copper

- Distalloy Materials

- Iron Nickel

Call us @ 216.870.1098 if you would like us to send you an electronic copy of the MPIF material standards book for Structural P/M components and Bearing applications.

Other Services Cook-Leitch Inc.’ provides:

- Oil Impregnating Systems with Centrifuge Equipment

- Vibratory Finishing for Deburring

- Heat Treating

- Steam Treat

- Drilling

- Tapping

- Machining

- Sizing

- Grinding

- Plating-Zinc Nickel, Standard Zinc, Black Oxide, Magni-Coatings, etc.

- Special Impregnation’s for Sealing/Coatings, and Assemblies

- 100% Non-Destructive Testing (NDT) via Vision and/or Resonance for safety critical Powder Metal parts.

Quality-Oriented:

- Our P/M facility is ISO9001:2015-registered.

- The key to our quality is…….

- Understanding the part application and function, and design a P/M part for manufacturability.

- Secondly, we have a very disciplined approach in designing high-quality, robust tools.

- We are diligent in our preventative maintenance of tooling-We protect our customer’s capital investment!!

- We monitor our quality throughout the molding, sintering, secondary processes (i.e. heat treat, machining, plating, etc.).

- We specialize in Safety Critical applications, and have a full QA Lab, including mechanical break-testing equipment for comparative yield strength, elongation, etc.

- Features a 5,000 sq. ft. Non-Destructive Testing (NDT) department-

- We can high-speed 100% inspect P/M parts via

- Auto Vision Systems

- Resonant (Sound) Inspection Systems

- Or, incorporate both NDT’ 100% inspection techniques for your safety critical P/M components.

- We can high-speed 100% inspect P/M parts via

Since 1964, Cook-Leitch Inc. has served a variety of industries with Powder Metal Components:

Appliances-Home & Commercial

- Dishwashers

- Washing Machines & Dryers

- Blenders & Food Processing

- Vacuum Cleaners

- Ovens & Ranges

Automotive

- ABS Braking Systems

- Steering Systems

- Seating Systems

- Door Hinge & Trunk Hinge

- Sensors

- Window lift actuators

- Anti-Vibration

Plastic Injection & Rubber Injection Molding

- Custom Metal Inserts

- Insert-Molded and Over-Molded Components

Stampings and Value-Added Assemblies

- Powder Metal parts (and Wire Forms, Machined Parts, etc.) which are Welded to Stampings in a Value-Added Assembly

Agriculture, Lawn & Garden, Power Equipment & Recreation

- Lawn Mowers–Push & Zero-Turn

- Snow Blowers

- Snowmobiles

- Transmissions

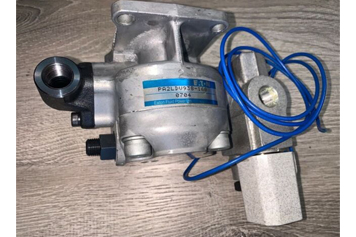

Fluid Power & Hydraulics

- Valves & Smart Valves

- Fittings

- Cylinders

- Pneumatic

- Pumps & Actuators

- Hydraulic Sensors

The Benefits of Powder Metal Components Manufacturing

The PM process offers a host of advantages over traditional metal manufacturing practices like forging or die-casting. These benefits include:

- Cost-effectiveness: PM reduces energy consumption, improves material utilization, and contains fewer steps than other manufacturing approaches, all of which help lower the impact on the bottom line by trimming costs up to 70%.

- Higher degree of customization: From the creation of unique alloy and lubricant blends designed to meet the material properties of a specific application to the ability to easily produce complex geometries like irregular curves and radial projections, key-ways, splines, counter bores, bosses, axial projections and more, PM allows for greater part customization than other metal manufacturing methods.

- Minimal machining requirements: With a superior ability to achieve close tolerances, less machining is necessary to produce a final product.

- Superior surface finish: Net-shaping and tolerance adherence contribute to a reduction in machining needs, which in turn improves surface finish.

- Repetitive accuracy: The process is suited to moderate- to high-volume production with excellent repetitive accuracy.

- Materials can be further tailored: Secondary operations allow components to undergo any additional treatments necessary to draw out the material properties most critical for an application’s success, like ductility or hardness.

All our produced are manufactured and/or distributed in the USA. Contact Us or Fill out the Form for More information

Cell:216-870-1098

Office: 440-356-5552