Metal Finishing

Metal Finishing—Cook-Leitch Inc. Has You “Covered”!

Cook-Leitch Inc. was founded in 1964 by Ronald Cook and Robert A. Leitch. However, it wasn’t until the late-1970’s when our OEM’ customers were seeking improved metal finishing and plating solutions for their respective components and products. Today, we have your metal finishing need “covered”—whether your product or tooling needs enhanced corrosion resistance, or requires improved wear resistance, or the surface needs increased hardness, and/or you need to improve the lubricity (reduce coefficient of friction), then we may have a solution for you.

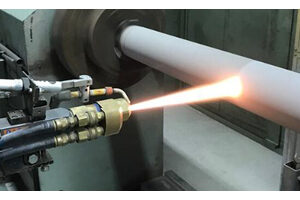

We provide “Metal Finishing” solutions for customers in the stamping, machining, die casting, tooling (injection, compression, composite, extrusion, pultrusion, rubber, and other tooling applications), Hydraulic & Cylinder Repair, as well as decorative chrome on plastic injection molded components. If you have a plating/coating requirement, our Metal Finishing partners will surpass your expectations!

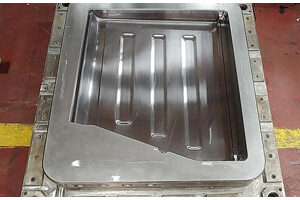

Cook-Leitch Inc. can provide coatings and plating on dies, fixtures, molds, and tooling:

What Types of Tools and Molds Do We Coat & Plate?

- Plastic Injection Molds

- Compression Molds

- Composite Molds

- Extrusion Dies

- Pultrusion Dies

- Rubber Molds

Our Goal is to improve your manufacturing efficiency—Longer production runs & less down-time! We can Improve Hardness, Enhance Wear & Lubricity for greater productivity.

What Coatings & Plating Do We Apply to Molds, Tooling, Fixtures, etc.?

- Anodizing of Aluminum

- Black Oxide

- Electroless Nickel

- Electroless Nickel + Teflon

- Electropolishing & Passivation of Stainless

- Hard Chrome (Industrial)

- Nickel Boron Nitride

- Proprietary Coatings—

- Thin Dense Chrome—a very thin (.0001” thick), yet extremely hard (Rc 70) coating. This thin-dense chrome plating will increase will reduce friction and improve wear.

- Coating of Rubber molds for long-lasting production runs.

- Proprietary polymers impregnated and baked into the chrome plating to fill the micro-crack structure of hard chrome and then polished to a mirror finish—this process provides an extremely hard finish with added lubricity. The typical thickness of this coating is .001”.

Cook-Leitch Inc. Specializes in the Plating of Stampings, Machined Parts, Castings, and Plastic Injection Molded Components:

We offer the following plating solutions for your production components—

- Anodizing of Aluminum

- A variety of colors

- Black Oxide

- Bright Dipping of Brass components

- Electroless Nickel

- Electroless Nickel + Teflon

- Electropolishing & Passivation of Stainless Steel

- Micro-Cleaning of metal components

- Standard Zinc plating (both rack plating and barrel plating)

- Clear

- Yellow

- Zinc Nickel (both rack plating and barrel plating)

- Zinc Iron (rack plating only)

In addition, Cook-Leitch Inc. provides Precious Metal Plating on stampings, terminals, machined parts, castings, etc.

- Copper

- Gold

- Nickel

- Platinum

- Silver

- Tin